The secret of eternal youth

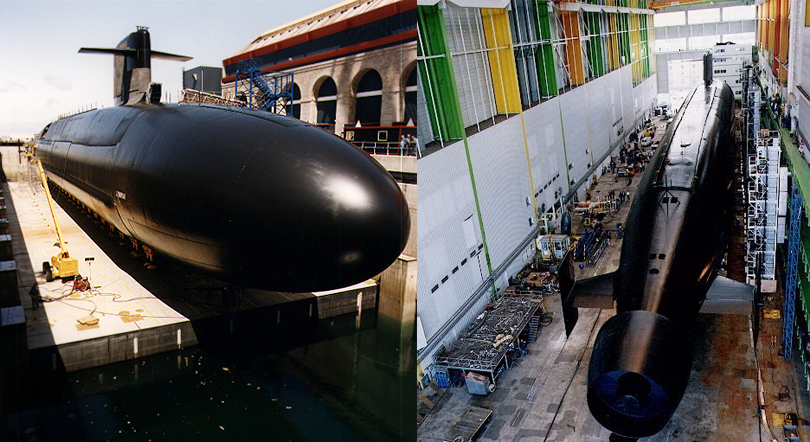

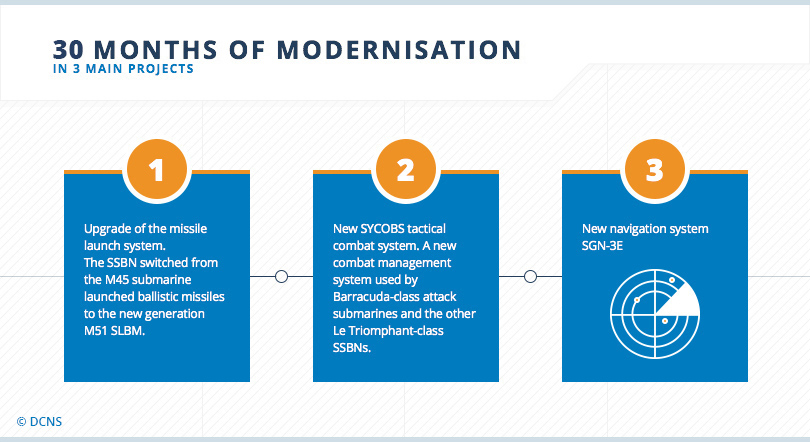

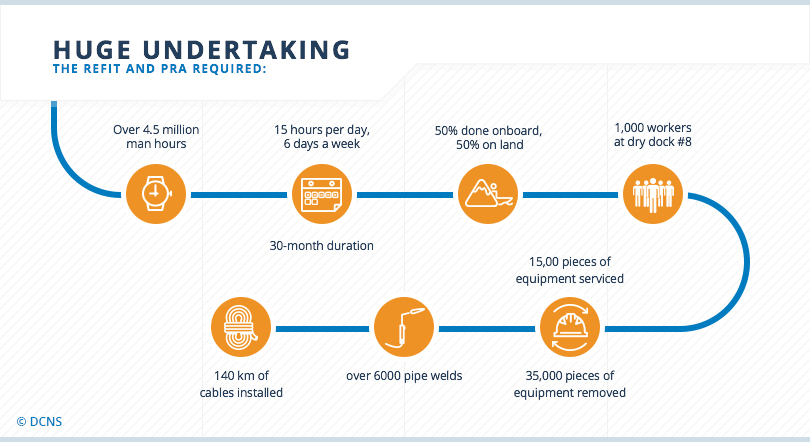

Warships are built to last. The average lifespan of a nuclear submarine, for example, is 30 years. But over its lifetime, a submarine it will undergo several overhauls to ensure that it remains at the cutting edge of naval technology. We take you inside the recent overhaul campaign of France’s Le Triomphant-class submarines to show you how our Eco Design thinking makes vessels ready for maintenance and overhauls from day one.

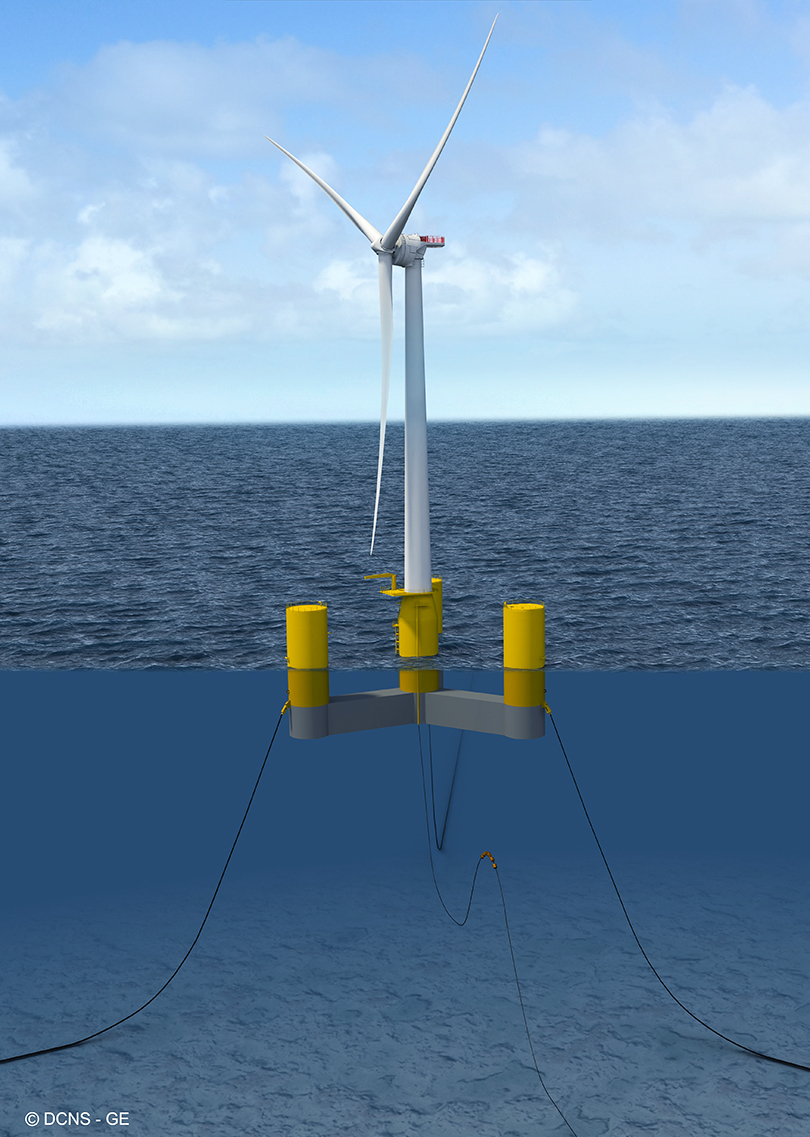

How to make wind float

On opposite sides of the Atlantic Ocean, Naval Group is combining its below-the-surface expertise with its manufacturing and integration capabilities to help make deep water offshore wind power a reality.

While wind farms have become a common feature of the landscape in many countries, the their offshore siblings, and in particular floating wind turbines, are just beginning to reach commercial maturity. Because winds tend to be stronger along the coast and there are many available areas, it makes sense to install wind turbines offshore. But so far, installation has been limited to relatively shallow waters because their foundations need to be installed directly on the seabed.

What if wind farms could be built in harbors and installed with a standard tug boat in deep water, where winds are strongest, without requiring underwater foundations or heavy offshore construction techniques?

This is the promise of floating offshore wind turbines.

In France

Instead of using towers embedded in the sea floor, an international consortium led by EOFLI and CGN Europe Energy are developing floating offshore wind power for operation in waters up to 200 meters (650 feet) deep. EOFLI is the French leader in floating wind power and CGN Europe Energy is a subsidiary of China General Nuclear (CGN) Power Corporation. This design was recently chosen by the French government for the Ile-de- Groix wind turbine pilot project in the Bay of Biscay. Naval Group and French construction firm Vinci will provide the submersible floating platform and General Electric will provide the turbines.

The turbine will be mounted on a semi-submersible platform that combines steel columns connected to a central concrete base. This so-called “hybrid” floater design is the fruit of Naval Group’s expertise in naval architecture and industrial production. Not only can it withstand offshore conditions and be moored to a wide range of sea beds with minimal disruption to the habitat, it can be manufactured at most ports using local steel and concrete manufacturing facilities. The floater will be between 40 and 60 meters wide. Thanks also to the floating design, the structures can be assembled in port rather than in open sea and brought back to port for heavy maintenance. This reduces the time and cost associated with assembly and maintenance by removing the need for lengthy offshore campaigns.

In the United States

In May 2016, the US Department of Energy (DOE) announced funding for New England Aqua Ventus, a 12-MW floating offshore wind pilot project initiated by the University of Maine. Naval Group is part of the winning consortium, along with the University of Maine, Emera and Cianbro.

The floating wind turbine hull design of the Aqua Ventus project was tested for nearly 19 months in Castine, Maine, using a 1:8-scale prototype. It was the first grid-connected offshore wind turbine in the Americas to send electricity into the power grid. It was also the first in the world to use a concrete hull.

Naval Group will use its expertise in naval architecture, mooring systems and marine operations to participate in developing, constructing and operating the floating wind turbines capable of resisting the harsh North Atlantic conditions. It will be built using the same concrete technology used in bridges and dams and can be built locally, thanks to Maine’s existing concrete manufacturing infrastructure. This helps to reduce construction costs while contributing to the local economic development.

Naval Group is playing an active role in helping develop the floating wind industry in both the US and France. With the projects in Ile-de-Groix and Maine, Naval Group is involved in the installation of two floating offshore farms comprising six turbines and 36 MW of power generation capacity. By 2020, when the first farms will be installed, other international projects will be in the works, and Naval Group aims at playing a major role in them.

A partnership between two international industrial compagnies GE's Haliade 150-6 MW offshore wind turbine and DCNS floating system.

Cool team player

The concept of interoperability lies at the heart of modern military operations. Behind this ungainly word sits a very human-centered idea of understanding each other, communicating and acting together.

In June 2016, the French FREMM Aquitaine, built by Naval Group, participated in the NATO anti-submarine operation “Dynamic Mongoose 2016,” which was conducted in Arctic waters near Norway. There the Aquitaine worked hand-in-hand with ships from nine allied navies. See how Naval Group’ design and engineering make interoperability a reality.

Dynamic Mongoose 2016

- NATO launches anti-submarine warfare exercise (ASW), Dynamic Mongoose 2016, in Norway. 4th edition of the exercise.

- 10 days in the Norwegian Sea in an area measuring 14,000nm2

Objectives

- Strengthen NATO naval interoperability.

- Surface vessels track and simulate attacks on submarines traveling from one point to another.

- Surface units travel between two transit points under simulated threat from submarines.

Participants

- 8 NATO allies: Canada, France, Germany, Norway, Spain, Turkey, the UK, and the US

- 3,000 sailors and aircrew

Fleet

- Four submarines from Canada, Germany, Norway and the US

- Nine surface ships including French FREMM Aquitaine

- Four maritime patrol aircraft

FREMM-CLASS AQUITAINE

- Multi-mission anti-submarine frigate

- Entered service in 2012

- First in the series of eight FREMM multi-mission frigates ordered by the French Navy.

PROVEN INTEROPERABILITY

- Aquitaine was one of two French FREMM frigates that participated in early 2016 in the Task Force 50 operations in the Persian-Arabian Gulf, alongside FNS Charles de Gaulle aircraft carrier and the American aircraft carrier, Harry S. Truman.

- NATO-standard external communications include Link 11, Link 16, Link 22 and JSAT tactical data links

- Secure chat sessions keep combat operations team in constant contact with all allied units

- Certified for highest NATAO responsibilities, including Air Defense Commander within carrier battle groups.

Building one from many

System. It is a world that we use all the time but rarely think about. Systems are everywhere. In our homes, the electric system is connected to the phone system which is linked to our home security system. In businesses, payroll systems are connected to accounting systems that are connected to billing systems that are connected to inventory management systems. But in each case, the systems are simply interconnected; they don’t work together to form a larger system.

Seamless integration

That’s not the case in today’s most advanced warships. Designing them requires the integration of multiple systems to create one floating system capable of executing multiple missions. No individual system can be disconnected from another. For example, a radar’s performance depends on the stability of the ship’s physical structure but also on electromagnetic compatibility with other electronic equipment. Combat systems need to be fully interoperable with other fleets and the entire system needs to be protected from cyberattacks.

This integration of systems makes the modern warship one of the most complex human-made systems on Earth, far more complex than just about any other vehicle. The Naval Group FREMM frigate, for example, comprises over 20 million lines of code, three times as much as a modern wide-body jet. But this complexity must remain invisible, so as not to interfere with operations.

Over the years, Naval Group has developed a very rare skill set: warship integrator. It is one of only a handful of military shipbuilders capable of designing and building warships that integrate myriad onboard systems from a whole host of suppliers (including itself) into one holistic warfighting system.

It’s all about the base

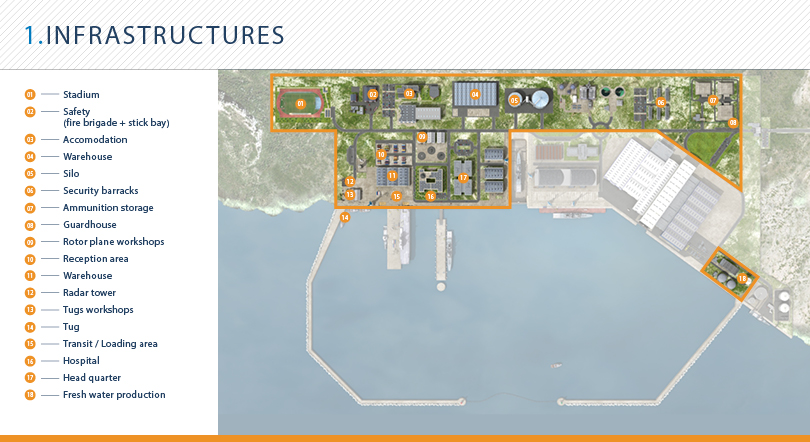

When nations build warships, they need to make sure they have the naval bases and infrastructures necessary to operate, maintain and later, upgrade their fleet.

The base can be thought of as the mother ship of the fleet. It’s location, design, facilities and operations play a vital role in fleet availability. An inefficient layout can hinder industrial operations; poor logistics can delay ship maintenance. Naval Group is one of the only shipbuilders in the world that also builds and/or upgrades naval bases and shipyards and provides technology transfer and training.

Here are seven things to keep in mind when building a naval base.

1. Site selection

As in real estate, location is everything when it comes to building a greenfield naval base.

Naval Group: Our services include site surveys and feasibility studies for new builds and audits of existing sites for upgrades.

2. Dimensioning

Design decisions today can save time and taxpayer money tomorrow. It is important to anticipate and plan for the requirements of your fleet today and tomorrow.

Naval Group: Based on experience with the French and other navies, our experts know how to dimension the base’s infrastructure in accordance with your operational needs and budget requirements.

3. Design

Designing a naval base and yard is just as complex as designing a state-of-the-art warship. The facility must take into account a wide range of operational, industrial, safety, security and logistical parameters.

Naval Group: We take base design into the future using virtual reality. This allows the engineers and specialists to simulate base operations and detecting potential conflicts and/or optimizations.

4. Engineering, Procurement and Construction Management

Design is only part of the job. The safe and successful execution of the construction project requires a best-in-class approach based on real-world experience.

Naval Group: Having executed several base constructions projects around the world, our EPCM teams know how manage and integrate the activities of the engineering, procurement, and construction phases of the project, including all subcontractor and suppliers. The result is fewer interfaces and a single point of contact. One of their know-how is also about the integration of civil works, outfitting and commissioning without disturbing the day-to-day operation of an existing naval base.

5. Commissioning

This vital step in the delivery of a yard requires perfect coordination between the shipbuilder and the base builder, especially in terms of qualifying infrastructure and equipment for fleet vessels.

Naval Group: Our experience in upgrading existing facilities and building new ones enables us to proactively reduce the risk of incompatibility between the ships and the port-side equipment.

6. Operations

Operating a naval base on a daily basis is a mix of complex facilities management and sensitive operations. What is the most appropriate model for base operations?

Naval Group: We can help determine the best Base Operation and Support (BOS) model and provide all the services necessary for daily operations, either directly or through our DES facilities management joint venture with Veolia.

7. Maintenance and beyond

Once the fleet and base are operational, the job isn’t finished. They become a living, breathing ecosystem that requires constant improvement and optimization.

Naval Group: We can plan, prepare and execute all types of maintenance on vessels and on the base itself. We also provide training and technology transfer to develop a local talent pool of sailors, designers, engineers and base operations personnel.